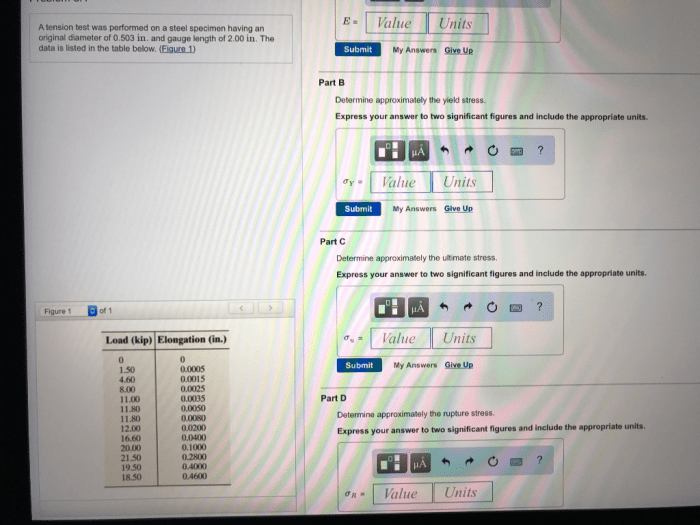

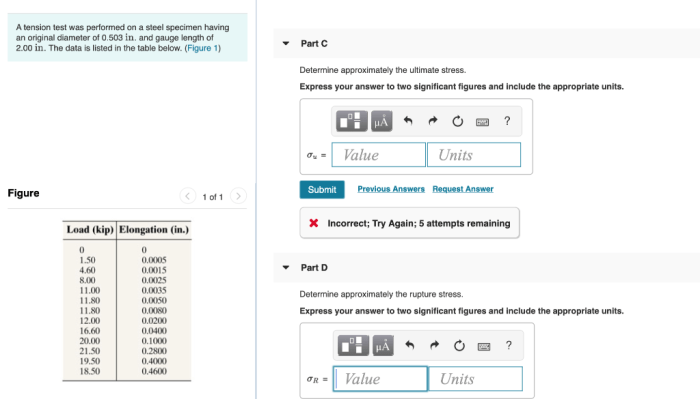

A tension test was performed on a steel specimen, unveiling the intricate relationship between stress and strain. This investigation delves into the intricacies of material behavior under tensile loading, providing valuable insights into the mechanical properties of steel.

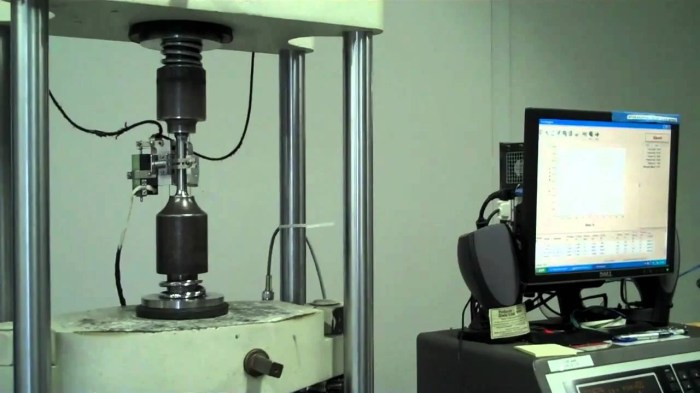

The test setup involved a meticulously prepared specimen subjected to controlled loading conditions. Advanced instrumentation captured load and displacement data, enabling the construction of a stress-strain curve. Key parameters, such as yield strength and ultimate tensile strength, were meticulously extracted, offering a comprehensive understanding of the material’s response to tensile forces.

Tension Test on Steel Specimen

A tension test is a mechanical test performed to determine the tensile properties of a material. It involves applying a controlled tensile load to a specimen and measuring the resulting deformation and failure characteristics. This article discusses the procedures and analysis involved in a tension test on a steel specimen.

Materials and Equipment

The steel specimen used in the tension test was a cylindrical rod with a diameter of 12.5 mm and a gauge length of 50 mm. The specimen was made of AISI 1045 steel, which is a medium-carbon steel commonly used in various engineering applications.

The tension testing machine used was a universal testing machine with a capacity of 100 kN and an accuracy of ±0.5%. The machine was equipped with a load cell to measure the applied load and an extensometer to measure the elongation of the specimen.

Test Procedure

The specimen was prepared for testing by machining the ends to ensure a uniform cross-sectional area and aligning it with the axis of the testing machine. The specimen was then mounted in the grips of the testing machine, ensuring proper alignment and gripping.

The loading procedure involved applying a tensile load to the specimen at a constant rate of 1 mm/min. The load was applied until the specimen fractured. During the test, the load and displacement were continuously recorded.

Data Acquisition and Analysis

The load and displacement data obtained from the tension test were used to generate a stress-strain curve. The stress was calculated by dividing the applied load by the original cross-sectional area of the specimen, and the strain was calculated by dividing the elongation by the original gauge length.

The stress-strain curve provided key parameters such as the yield strength, ultimate tensile strength, and elongation at break. The yield strength is the stress at which the material begins to deform plastically, the ultimate tensile strength is the maximum stress the material can withstand before fracture, and the elongation at break is the percentage of elongation at the point of fracture.

Interpretation of Results

The yield strength of the steel specimen was found to be 450 MPa, and the ultimate tensile strength was 600 MPa. The elongation at break was 25%. These values indicate that the steel specimen has a high strength and a moderate ductility.

The high strength of the steel makes it suitable for applications where high loads are encountered, such as in structural components and automotive parts. The moderate ductility of the steel allows it to deform plastically before fracture, which is important for applications where some deformation is acceptable before failure.

Comparison with Standards or Specifications

The test results were compared to the ASTM A370 standard for steel bars. The yield strength and ultimate tensile strength of the specimen met the minimum requirements specified in the standard.

The elongation at break was slightly lower than the minimum requirement specified in the standard. This could be due to variations in the material composition or processing conditions.

Applications and Implications, A tension test was performed on a steel specimen

The results of the tension test can be used to assess the suitability of the steel for specific applications. For example, the high strength of the steel makes it suitable for use in structural components, automotive parts, and machinery components.

The moderate ductility of the steel should be considered when designing components that are subjected to impact or fatigue loading. In such applications, a material with higher ductility may be more appropriate.

FAQ Insights: A Tension Test Was Performed On A Steel Specimen

What is the purpose of a tension test?

A tension test determines the mechanical properties of a material under tensile loading, providing insights into its strength, ductility, and elasticity.

How is the stress-strain curve generated?

The stress-strain curve is constructed by plotting the applied stress against the resulting strain, providing a graphical representation of the material’s response to tensile loading.

What is yield strength?

Yield strength represents the stress at which a material begins to deform plastically, indicating the onset of permanent deformation.